①Cooperative development of new techniques and technologies

By sharing the knowledge, techniques and technology of each company, new techniques and innovations can be born, which in turn can raise the overall level of Fukushima’s metal works as a whole.

②Fortification of local relations through collaborative process management

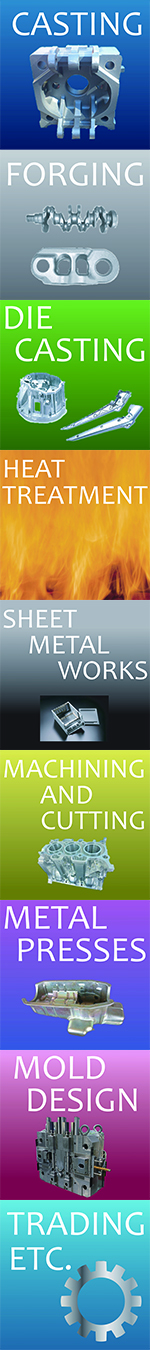

Deliverables to clients follow a very common production flow starting with procurement of iron casts, die casting, heat treatments, and then to the actual metal works, all done within the various foundries. But when they do not have the proper facilities, those works are often sent outside of the prefecture. By keeping these works within the group, it complements the process, while keeping the work local, leading to improved relations and overall productivity as a group.

③Promoting international development and cooperative ordering

The difficulties of going global as a mid/small size corporation can be alleviated as a group. Information sharing and business such as joint placement and receipt of orders can be promoted cooperatively with international partners who then can contact directly to order various parts and services. Our conglomerate group can participate in international events, leading to further partnerships. Even international orders received can be shared among the group and then properly allocated for best deliverable results through our heat treatment and machinery and then to our clients.

④Cost reduction through cooperative purchasing of materials

Through the shared purchasing of materials with multiple companies, a scaled merit of cost reduction can be attained. In addition, transportation costs can also be reduced through bulk purchasing with our local participating companies.

⑤Cost reduction through recycling within the conglomerate

We will seek cost reduction through the recycling of by-products within the group. Metal and machine works, metal stamping, sheet metal works, and other forging industries by nature create by-products. Usually, these are purchased by other parties who then add a margin and sell them back to the industrial cycle. By allowing direct purchase of such waste materials for reuse within the group, it serves to not only recycle, but also raise profit for sellers and reduce associated costs as a whole for buyers.

⑥Cost reduction through cooperative disposal of industrial waste

Being an industry where we deal with metal works, similar industrial waste is created through the manufacturing process. Industrial waste such as sand waste, wooden palettes, used wood molds and the like can be mass handled by a common source between the companies to reduce overall transportation cost and provide an opportunity for further cost negotiations.

⑦Sharing investment in energy efficient facilities

By sharing investment in energy efficient facilities, cost reductions can be expected. Instead of each company paying consultation fees, by sharing existing energy efficiencies, prevention of dust, effective dust collection, exhaust facility implementation and maintenance can be pursued to optimize the general layout. Investment sharing can also help prevent energy loss and reduce production mishaps which also reduce costs. These endeavors will be pursued further.

⑧Promotion of local community efforts

We are raising our youth to become talented engineers and are planning for BCP to promote our local communities. By holding periodic meetings with people within the local network, we not only promote local communities, but also instigate new developments that offer opportunities for training. This then offers an opportunity for those involved to generate revenue and promote the community. The various connections here lead to synergy within our conglomerate.

DOwnload

TOPICS

information

白河素形材ヴァレー

〒961-0302

福島県白河市東上野出島字笹久保

2番地

2 Sasakubo Higashikaminodejima Shirakawa,Fukushima,Japan

TEL.0248-34-3971

FAX.0248-34-3973

TEL +81-248-34-3971

FAX +81-248-34-3973

![]() info@shirakawa-valley.com

info@shirakawa-valley.com